Processes

IN HOUSE FACILITIES

The Rockwood Group excels in providing specialist knowledge, capabilities, and skills in technically demanding sectors. We leverage a broad range of engineering tools to deliver robust manufacturing solutions, such as carbon fiber manufacturing.

Our greatest asset is our experienced staff, who bring decades of expertise in materials, design, development, and serial manufacturing. This expertise is complemented by state-of-the-art tools, equipment, and infrastructure.

We utilize SolidWorks and Catia CAD systems to design and analyse components and tooling with precision. The transition from CAD to tooling and subsequent physical components is seamless, thanks to HyperMill, which generates cutter paths for our 3, 4, and simultaneous 5-axis machining centres. This ensures a complete in-house tooling and component machining capability.

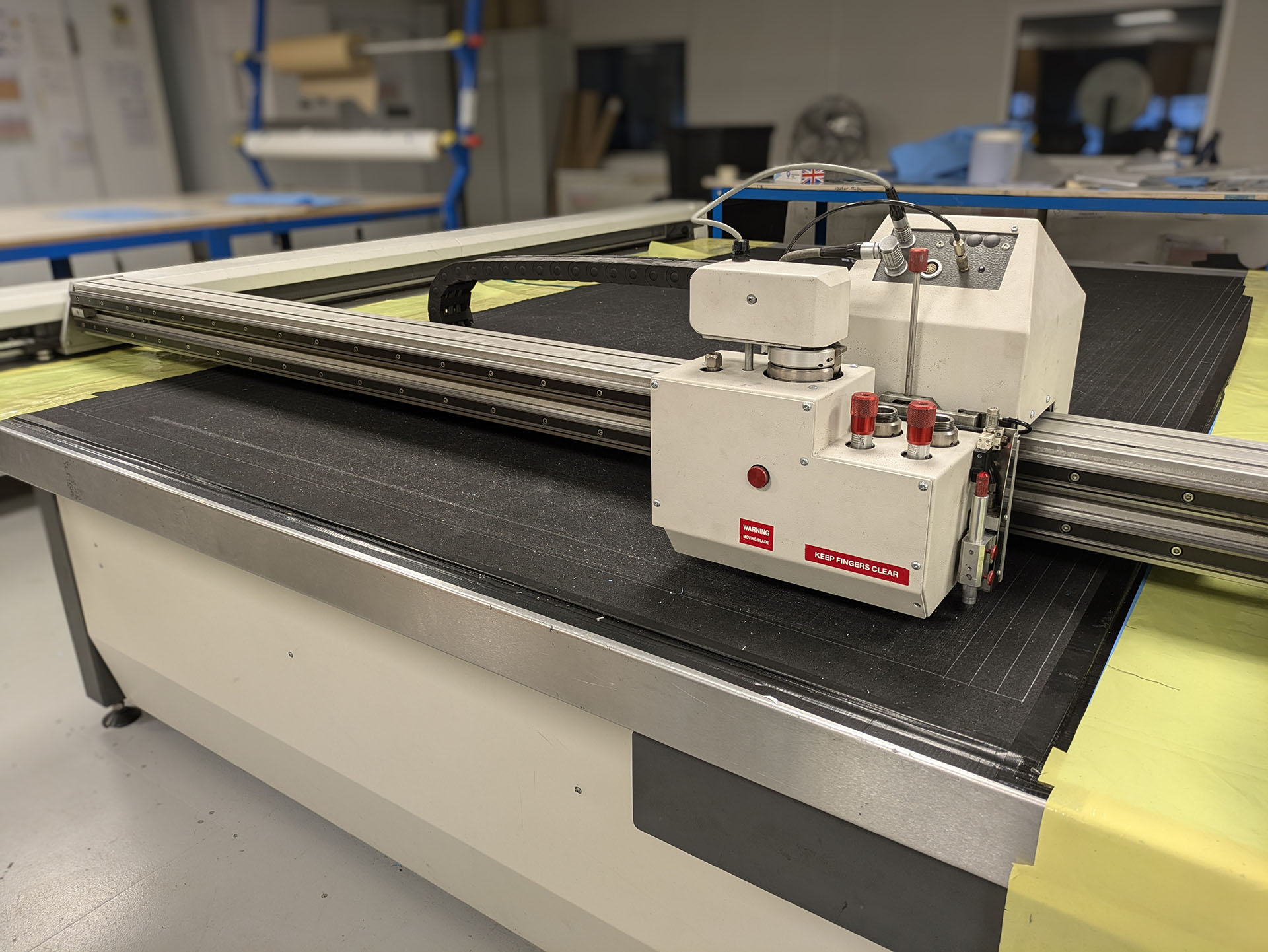

For composite manufacturing, we employ specialized equipment, including multiple -18°C cold storage units for material stock and two parallel ply cutters for precision-cut pre-preg materials.

Our composite processing optimizes pressure, temperature, and vacuum conditions to handle the full range of pre-preg resin systems, including carbon fiber manufacturing. Throughout production, processing conditions are meticulously logged and recorded as part of our quality assurance measures, supported by the latest laser scanning metrology.