Processes

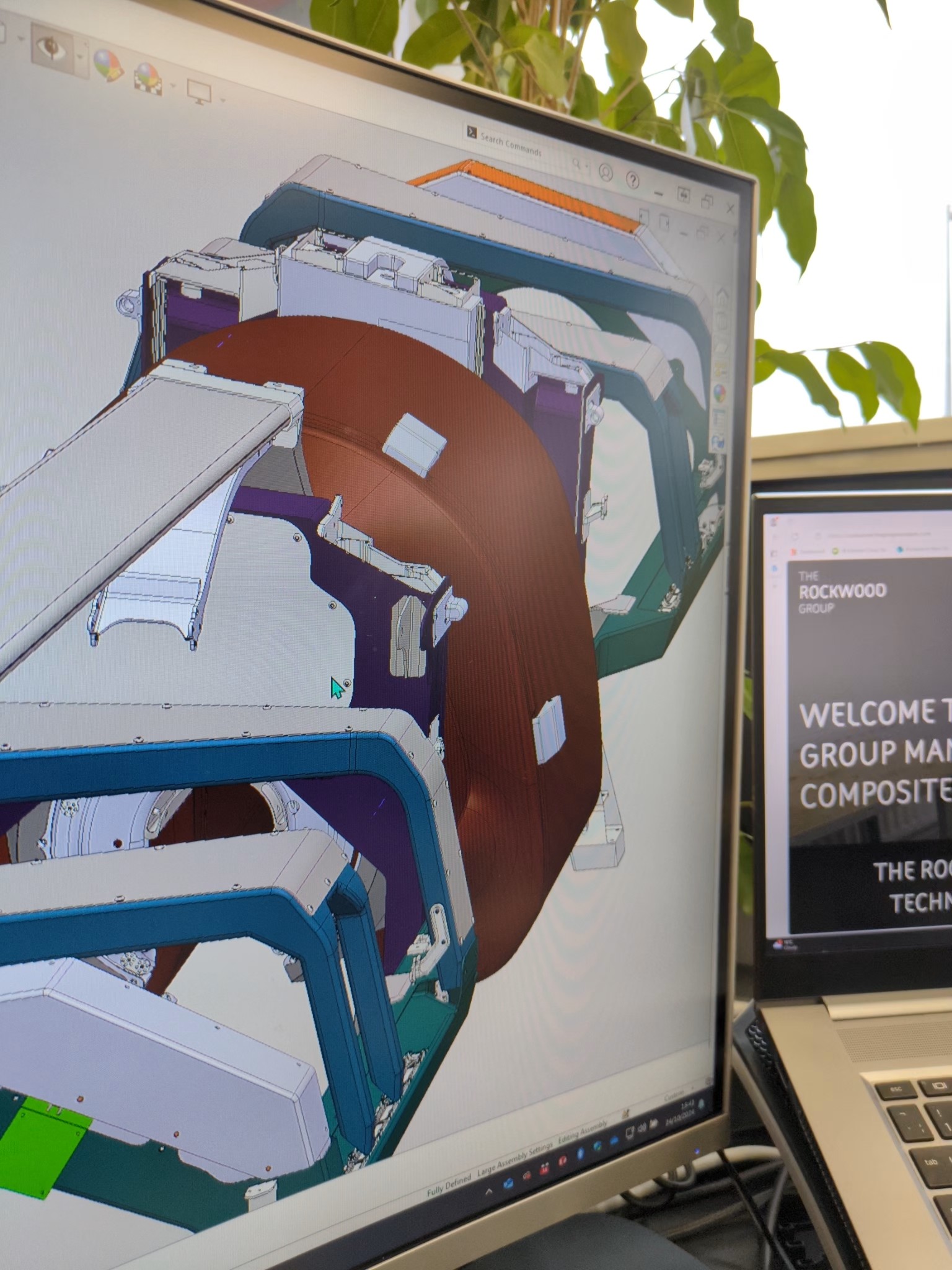

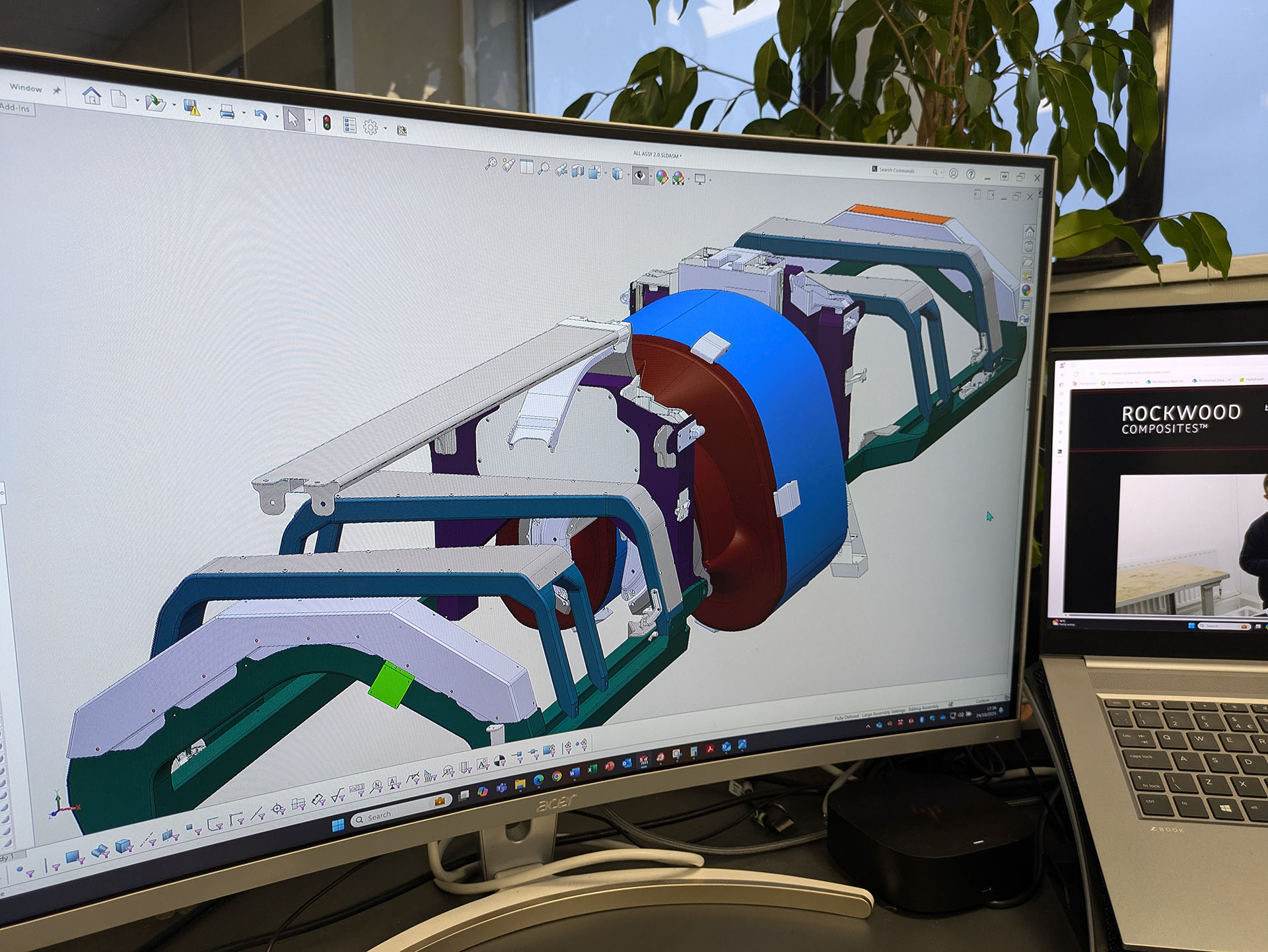

ENGINEERING AND DESIGN FOR MANUFACTURE

At Rockwood, we design and manufacture our own metal tooling to incorporate process optimization from the outset. We collaborate closely with our customers to ensure their parts are designed to optimize manufacturability, increase quality and maintain or even add functionality into the components. Our bladder and compression moulding processes result in high-quality components with a high fibre volume fraction and minimal voids. Wherever possible, we incorporate CNC machining features to eliminate handwork and trimming, ensuring that good quality tooling leads to superior quality and cost-effective parts in our composite manufacturing.

Our composite manufacturing tooling can be designed to be configurable, meaning a single tool can feature interchangeable inserts to enable the production of various similar parts. We offer a selection of tooling materials, including aluminium, invar, and steel tooling to work in our heated platen presses.

Stand-alone tooling can be built specifically to customer requirements and can incorporate integral heating and cooling systems, bladder and compression moulding within the same tool, multi-zone heating, and fully automatic cure control. These tools are fully autonomous, allowing for fast component turnaround without the need to move them in and out of heated presses.